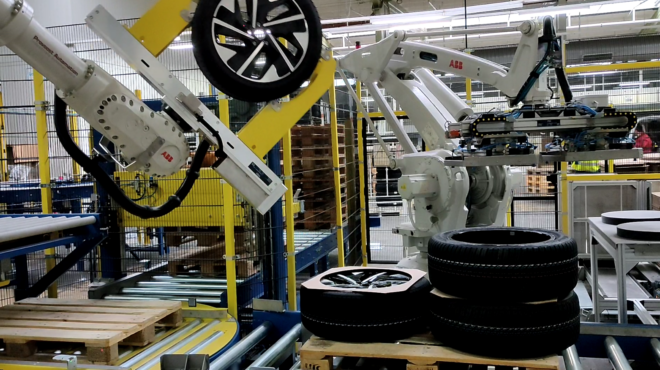

Robotic paletization of wheels

Robotic palletization of complete wheels for an international customer in the automotive industry.

ADVANTAGES: ROBUST CONSTRUCTION, RELIABILITY, HIGH PERFORMANCE, PRECISION

| Basic description | Destacking of the TWA and than palletising to the wooden EUR pallet. Inserting the paper interlayer between the layers and following wrapping and DHL label aplicating. |

| Guaranteed machine performance | 60 pallet /h -> 15sec/wheel |

| Handled goods – dimensions/weights/orientations | Complete wheel – TWA 14“ – 20“ -> Ø 550 – 780mm, H= 165 – 330mm, váha weight. 12kg-45kg |

| Layer pattern (orientations) | One layer – 2 TWAs next to each other in two layers |

| Number of products per layer | 2 |

| Number of layers on pallet | 2 |

| Layer pads between layers (number) | Type A – paper cardboard 580×580 – annulus – viz. layout

Type B – paper cardboard Ø 505 – viz. layout Both types are delivered as one piece – they are cutted between each other-there is neccessary do divede them by robot head. |

| Pallet dimensions, material and oreintation | Eur pallet 800×1200, max. 1000×1600 in the future |

| Number of empty pallets in the stack | 12 |

| Maximum pallet hight | Complete height 750mm with the pallet |

| Product change – method | Automatic |